Prometheus Eco Racing is the energy efficiency racing team of the National Technical University of Athens – School of Electrical and Computer Engineering. Out team’s members, undergraduates and PhD candidates from various scientific fields, design and build high efficiency electric, vehicles competing in the annual Shell Eco Marathon efficiency and innovation competition against universities from all over the world. Working under the pressure of demanding deadlines, the team’s members broaden their academic knowledge, theoretically and practically and gain great experience.

Our vision is to bring light to sustainable and efficient solutions for the electric and generally the automotive industry as well as advance the battery – electric vehicle technology. With a hand-made, eco-friendly, prototype electric vehicle constructed from scratch, an 1.000 km trip will now cost less than 30 cents of a euro.

Responsible to represent the team in the academic community is Antonios Kladas – Professor in the Division of Electric Power of the Department of Electrical and Computer Engineering in the NTUA. The team’s members have six main sections work on according to their field of studies and talents. All of them are coordinated and organized by the team captain.

Team Sections

Powertrain

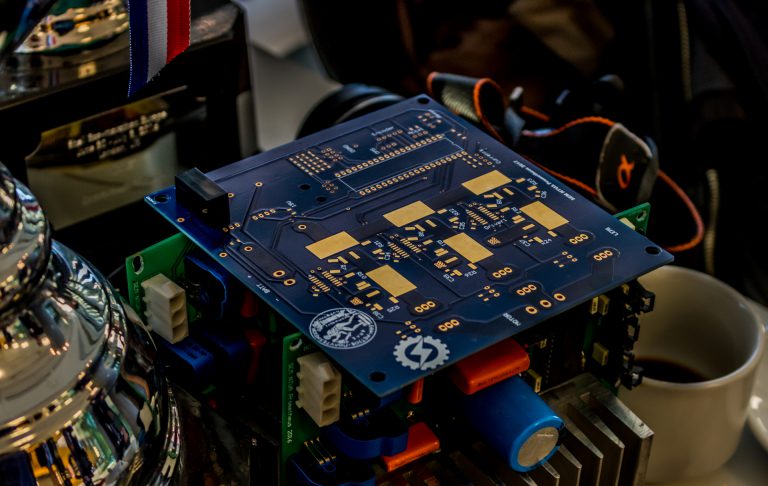

This system is the backbone of an electric vehicle, whether it is a research vehicle or a commercially available vehicle. Its main components are the power source – the battery – the electronic converter and of course the electric motor. During the 11 years of our competition, our team has designed manufactured and tested three 3-phase permanent magnet motors and also inverters with discrete switching elements and ICs. Our team is also involved in the implementation of control algorithms for our electric motors with microprocessors and control schemes applied in industry.

The 144Wh lithium-ion battery pack supplies the inverter with continuous voltage and current. The inverter then converts the battery power to three-phase power, suitable to power the motor, according to the torque or speed commanded by the driver. The three-phase permanent magnet motor operates at a wide range of speeds with constant torque and high efficiency, so no gearbox is needed in contrast with conventional vehicles.

In addition to those vehicle systems, our team also designs experimental setups for experimental confirmation of the good operation and performance of all the above structures, such as loss measuring devices for power electronics PCBs. We also model the behavior of the subsystems in the vehicle and derive qualitative and quantitative conclusions which, in conjunction with the experimental studies, help us improve our systems.

Electrical Systems

The team dedicates a considerable amount of time to developing auxiliary systems that will ensure the smooth operation of the vehicle, monitoring some of its operating characteristics, as well as the concerning about the safety of the driver and vehicle systems. Some of the topics we deal with in this context are:

- The design and construction of a telemetry system for the purpose of retrieving, processing and storing data and transmitting some of them in real time

- The construction of a precise positioning system for the vehicle

- Designing boards for security and power circuits

- The manufacture of plugs and connectors for all parts of the vehicle

- The design and construction of electronics for our 3D printed steering wheel

- Electronics safety circuits

These systems, instead of being necessary for the smooth and efficient operation of the vehicle and human safety, have also brought the team awards for their innovative operation within the Shell Eco Marathon.

Vehicle Simulation and Driving Strategy

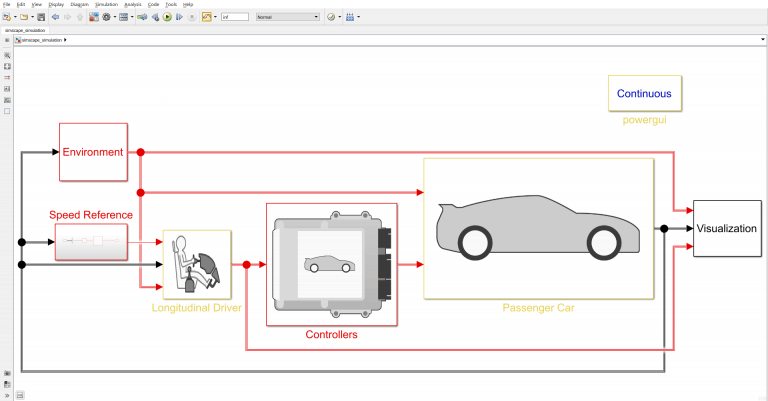

Which velocity is the car supposed to drive to consume the least amount of energy?

How can we boost the performance of the car?

All of these questions and more come together in our driving strategy. The main idea is to validate and tune the performance of the system with the aids of certain methods and tools. In order to accurately answer those questions, we first need to be able to model our Vehicle in a simulated environment. The art is to analyze and predict the behavior of the car on track, by knowing both inside and out. That is the main reason that, when creating simulations, one should work closely together with the whole team, so sufficient information as input is assured. Finally, a plan is evaluated, taking into account the track (curves, hills, …), weather, safety, battery capacity, tire wear, etc. And last, but not least: a bit of luck!

Chassis and Vehicle Dynamics

Friction, it is all about friction. The challenge that never stops for the mechanics. Every part, every detail, everything has to be optimized to minimize friction. That’s one of the problems this sub-team has to face. Trying to minimize the friction and rolling resistance in order to minimize wasted energy and maximize efficiency.

At the same time, the frame of the car need to be rigid and able to withstand all of the forces that could possibly be applied to it, while at the same time be safe for the driver in any event; even on this of a crash!

Finally, this sub-team focuses on weight. Each part is made as light as possible, every gram is counting. Stronger and lighter materials are used. Aluminium chassis and parts and Fiberglass shell reinforced with Carbon Fiber and Kevlar have achieved a weight less than 34kg.

Aerodynamics

Why do raindrops have the shape they have when falling from the sky?

Well, because a raindrop is the most aerodynamic shape in nature of course! What that mean is that, when moving through the air (or any other material to be exact), the force applied to this shape, opposed to its movement, is the least possible comparing to any other shape.

So, as you probably guessed by now, when you try to design and build efficient vehicles you need the least amount of force opposing to your movement. And that’s exactly what the Aerodynamics sub-team is working on. Of course you also need enough downforce in order to stay on the ground and be able to take turns without needing to push on the brakes.

Marketing and Design

As you can imagine, a project of this scale gets a lot of attention while at the same time needs a lot of funding to come to life. Those are some of the thing that this sub-team works on.

As for design, out team designs everything that they need by them selves, from our team’s booklets, brochures, website and logo to the team’s official clothing, everything is designed, reviewed and evaluated between the team members.

Also, this sub-team is responsible for all of the events we attend, as well as all of the events that we need to organize. Last but not least, they are trying to show our work in the best way possible, they are responsible for the way our team appears on the Media and also for the communication with the community and our Partners.